Any Material and Any size Excavator!

The 2023 Excavator screening bucket range allows for any material. And it is also suitable for any size carrier!

All with high efficiency and no shaking!

So you can move anywhere and screen anything with efficiency and comfort.

Our screening buckets have several leading advantages. Such as:

- Zero Daily maintenance and,

- Changing the mesh in under 5 minutes, on-site, with no tools and one operator.

- Smart Valves allow for any hydraulic flow and pressure, without modification of the excavator.

- Plus many more: Flipscreen Benefits.

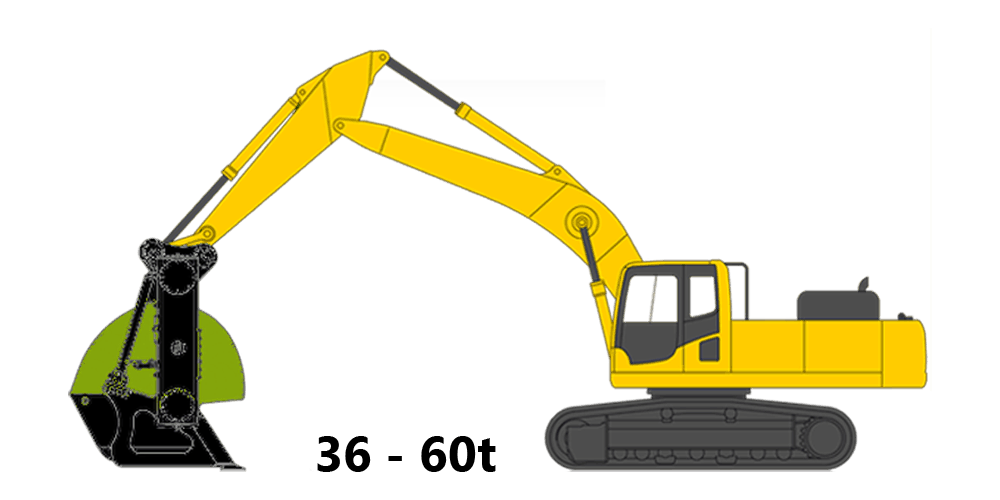

Excavator Screening Buckets for sale:

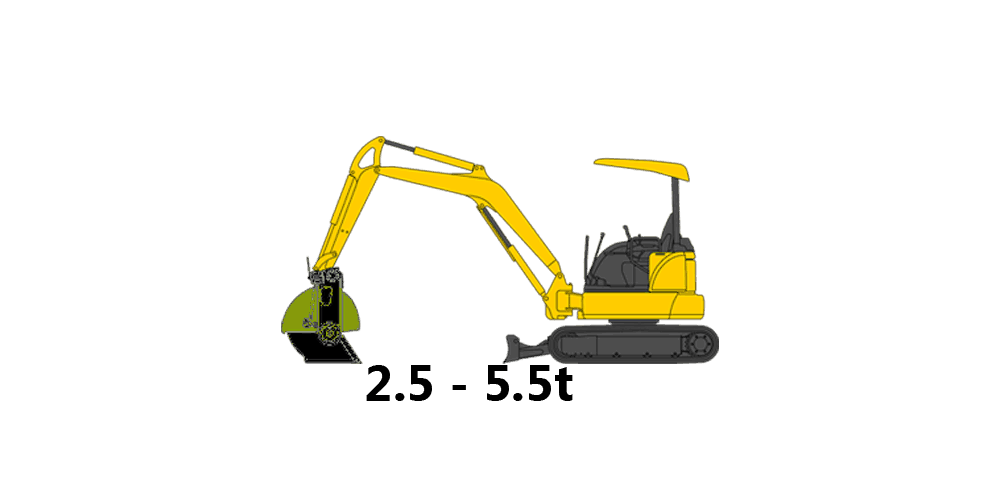

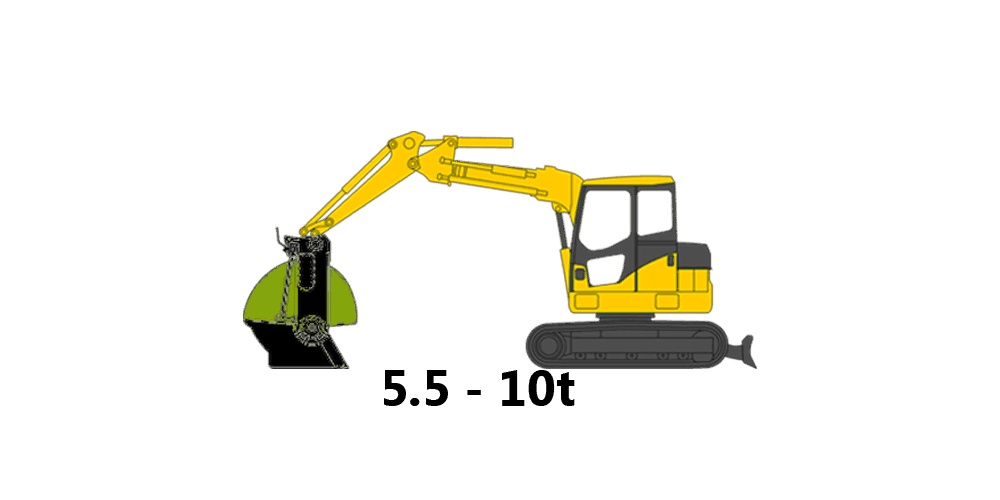

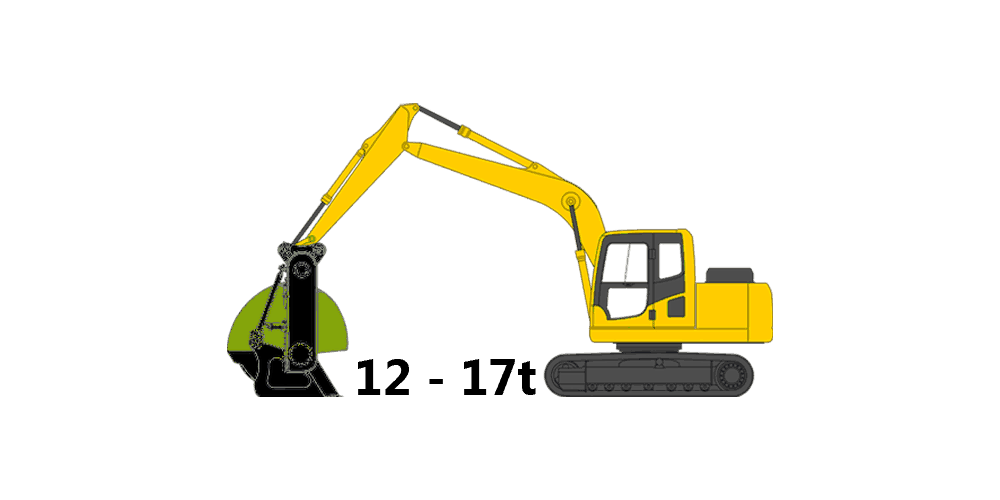

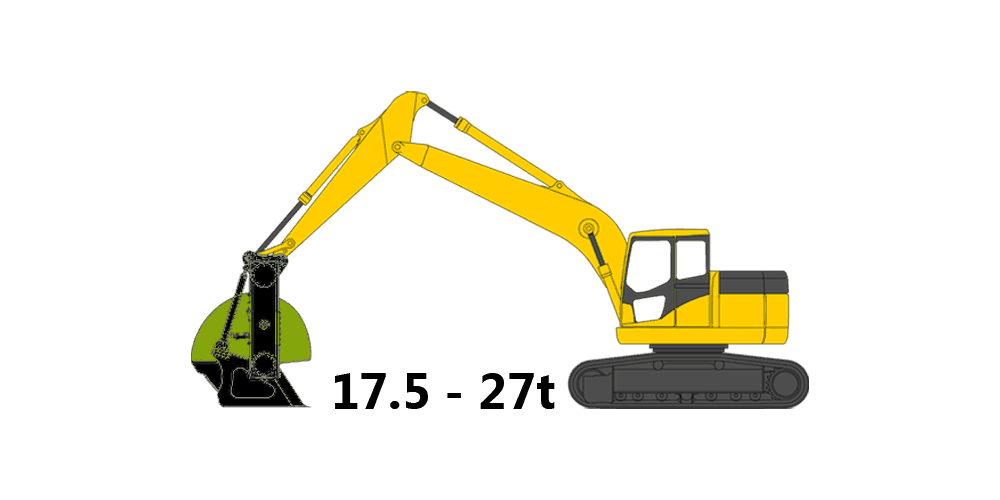

Pick your carrier size and see the relevant product.

Mini Excavator Screening Bucket:

The E30 Excavator screening bucket has proven invaluable in trench filling applications! Plus many other industries such as construction, waste recycling, and scrap metal recovery.

It can also screen and recycle materials onsite! And will slash your disposal fees, transportation costs, and material purchases. Inexpensively and efficiently screen materials, e.g. Scrap Metal and Concrete.

Made to be super tough, and suited to excavators sized 11,020 to 22,050 lb (5 to 10 metric tonnes). And also has super high-tensile mesh screens that range in size from 1/4″ to 12″ (6 mm to 300 mm). Changed in under 4 minutes. The unit also uses a smooth 360-degree rotating action with no shaking or vibrating. So it dramatically increases the effective life of your excavator.

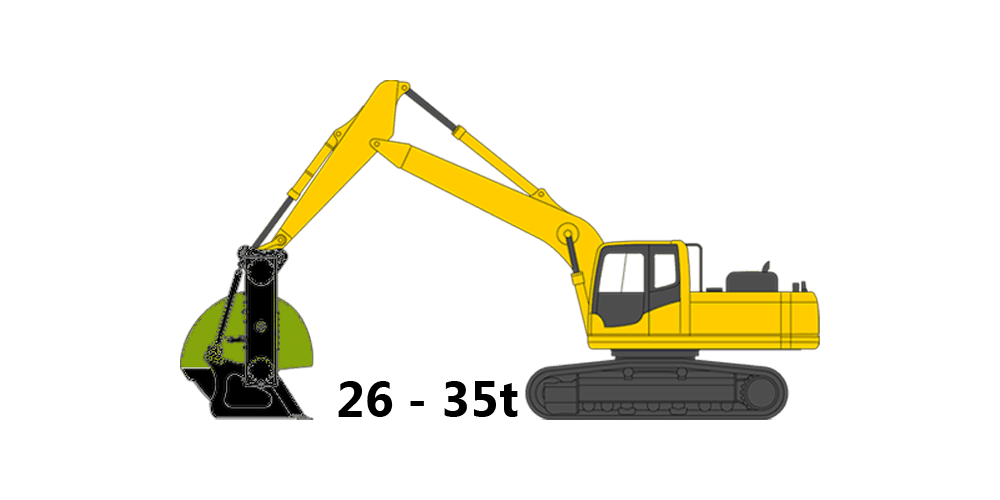

Excavator Screening Bucket:

The EX140 Excavator screening bucket is ideal for harsh materials. Which includes industries such as earth-moving, demolition, mining and stone quarries. And is suitable for 55,120 to 77,160 lb (25 to 35 metric tonne) excavators.

Engineered for extreme robustness, features include:

- double-sized veins,

- thicker wall and deflector plates,

- baffle supports,

- baffle impact plate and

- drain plug protectors.

The unit can also be ordered with either a bolt-on leading edge or teeth. And has a 70 square feet screening surface area. Plus High capacity motors generating maximum torque. So a screening capacity of 1.7 cubic yards (1.3 cubic meters) makes the EX140 super productive. Mesh size change occurs on-site, with no tools, and only one operator in under 5 minutes. These super high tensile mesh screens range in size from 1/4″ to 12″ (6 mm to 300 mm). Furthermore, this bucket’s smooth action also ensures there is no jarring or vibrating. This increases your excavator’s life.

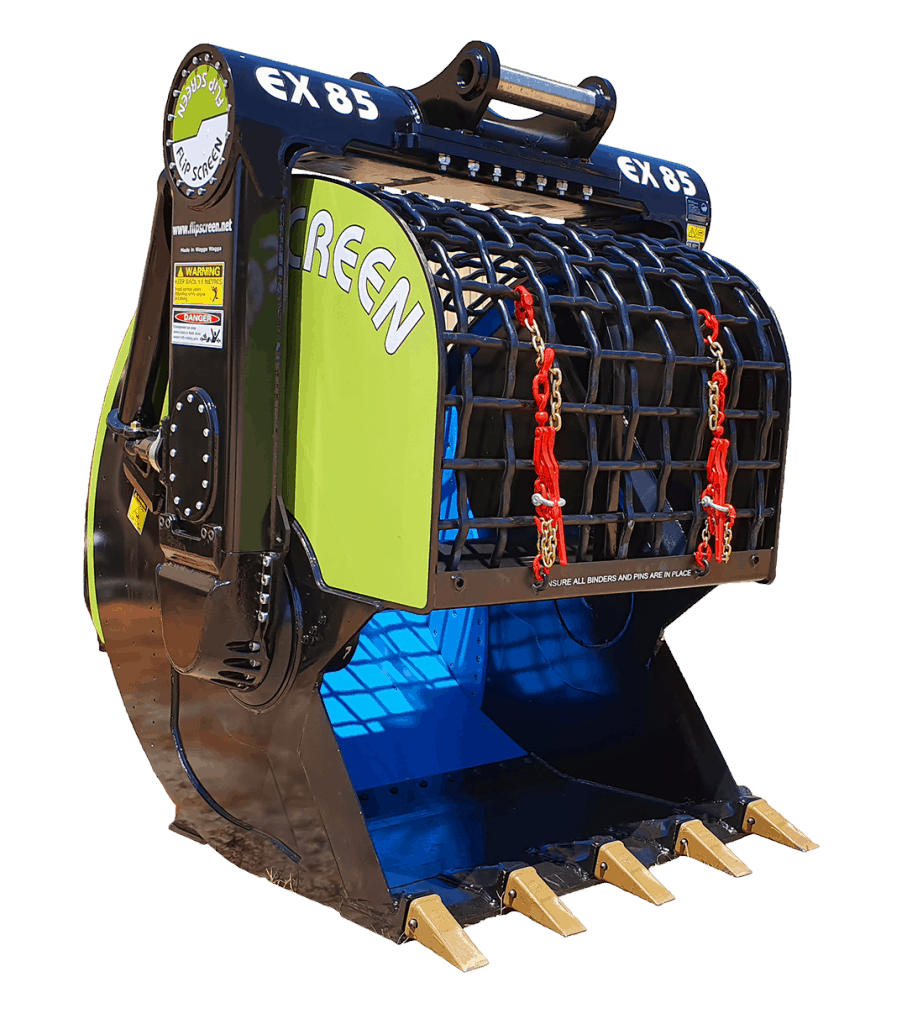

Latest Excavator Screening Bucket technology:

Flipscreen is very excited about the latest model we have to offer. The EX85 DD is the worlds most advanced screening bucket. It offers the following features:

- Chromium/ stainless steel bushings that eradicate the need for daily greasing.

- A reconfigured machine, to incorporate two-speed bent axis driven planetaries. Each drive can take the weight of the carrier machine several times over.

- Reduced fowling. Internal ribbing replaced with sweeping radiuses, which removed extra framework. And introduced non-stick hopper lines that are highly durable.

- The hopper lines also greatly reduce noise. Due to a reduction in harmonic vibration from material previously striking metal.

- A soundless unit from added external hydraulic cylinder to ratchet system. This cylinder design omitted hoses to eradicate hose damage.

- A cylindrical smart valve for greater space-saving.

- Flex point shock absorbers strengthening the machine. This allowed for the removal of excess steel, reducing the weight. Lower weight equals greater scoop volume.

Excavator screening bucket videos...

Excavator screening bucket customers...