6 a.m - 9 p.m (Mon - Sun)

contact@strongx.com

+259 (0) 256 215

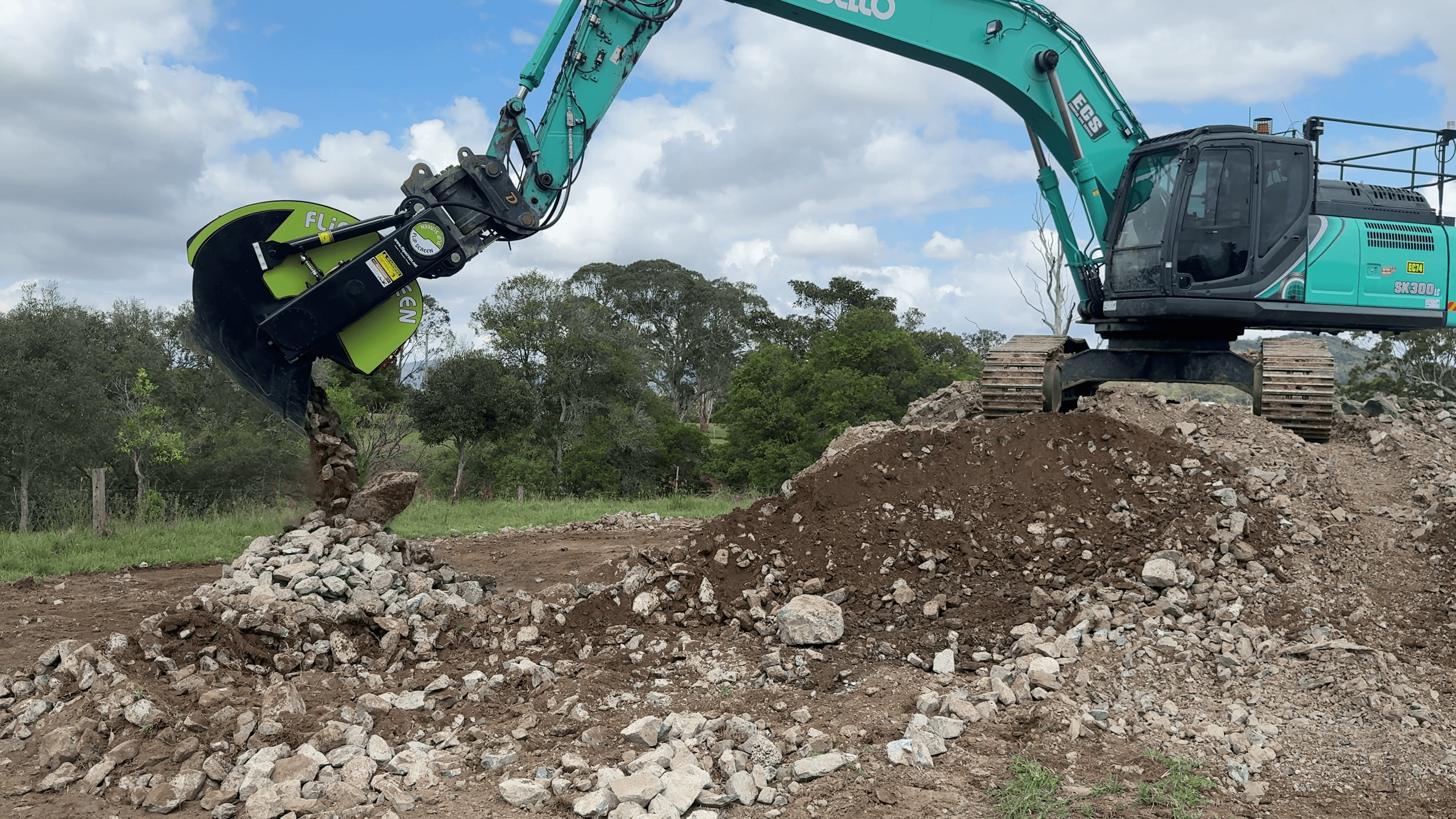

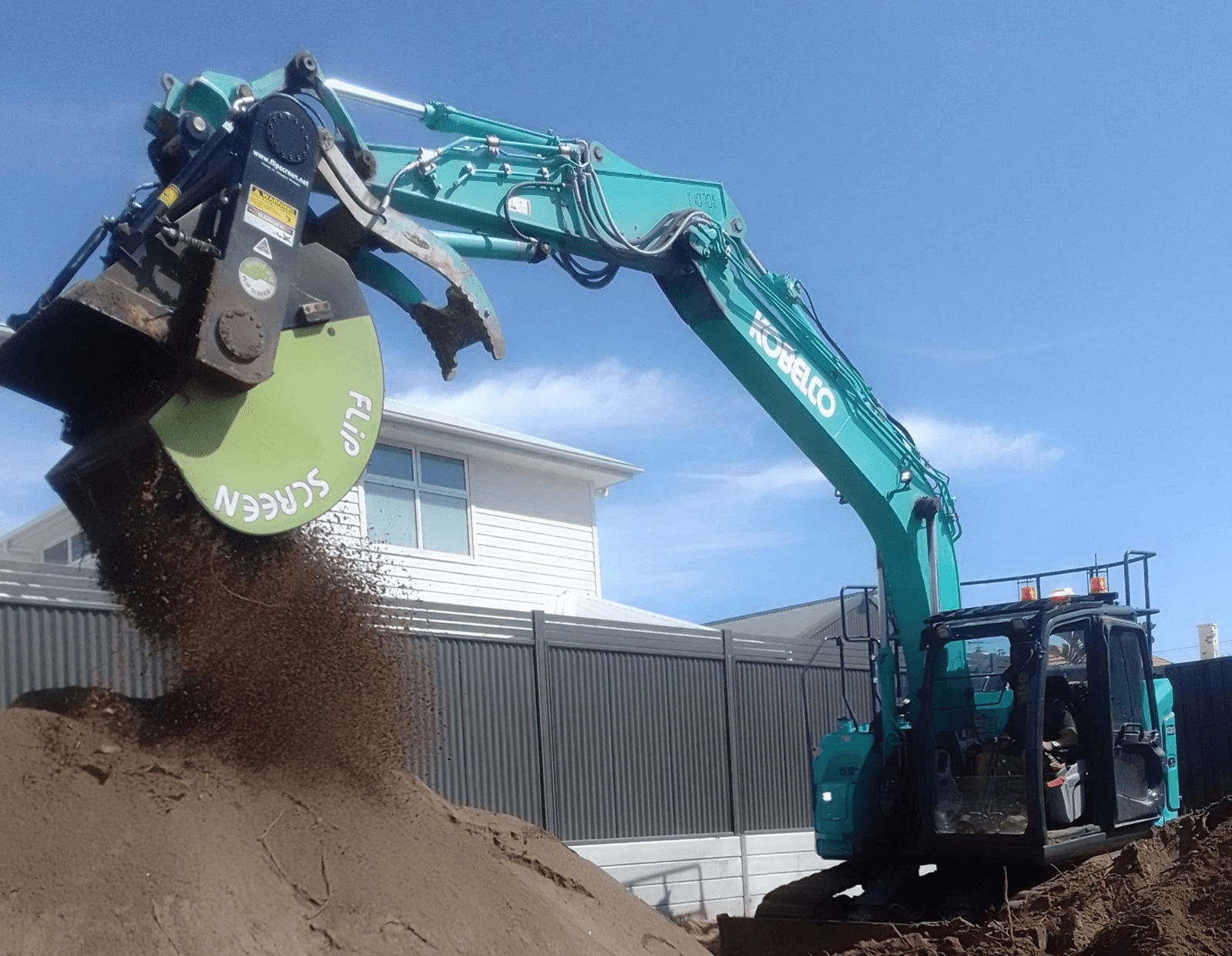

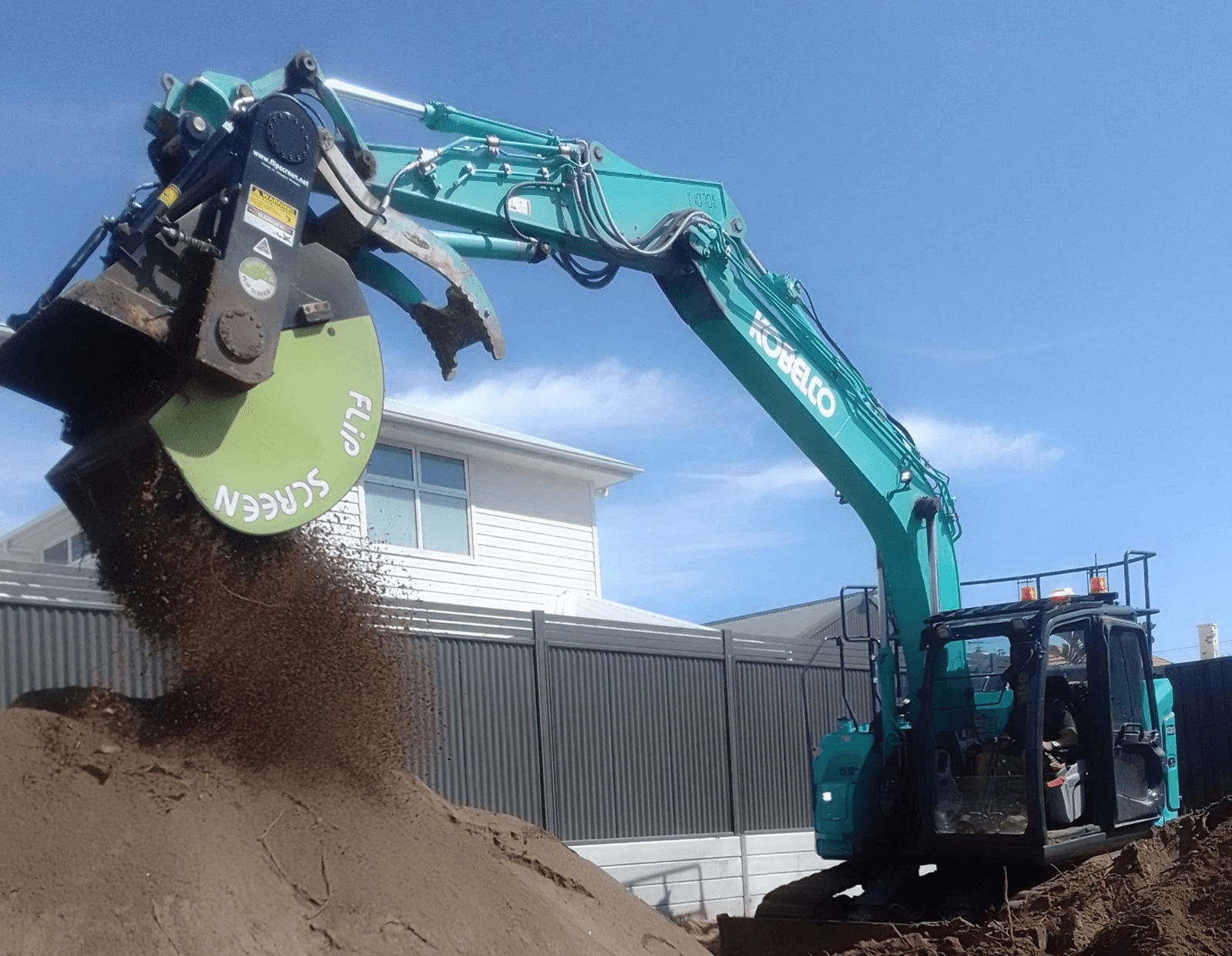

tHE WORLD'S BEST

SCREENING BUCKET

tHE WORLD'S BEST

SCREENING BUCKET

tHE WORLD'S BEST

SCREENING BUCKET

tHE WORLD'S BEST

SCREENING BUCKET

Recovering 300+ Tonnes of Scrap in Two Weeks

PSC Metals

Transforming Waste Streams into Saleable Products

Wagga Wagga City Council

Restoring 200 Tonnes of Clumped Urea

Private Contractor

Turning Muddy Concrete into Reusable Product

Conway Concrete Recycling

Saving $50 - 80k Annually by Screening Waste Soil With a FlipScreen

Southern Scape Retaining Walls and Excavations

What OTHER

FLIPSCREEN

USERS say

Recovering 300+ Tonnes of Scrap in Two Weeks

PSC Metals

Transforming Waste Streams into Saleable Products

Wagga Wagga City Council

Restoring 200 Tonnes of Clumped Urea

Private Contractor

Turning Muddy Concrete into Reusable Product

Conway Concrete Recycling

Saving $50 - 80k Annually by Screening Waste Soil With a FlipScreen

Southern Scape Retaining Walls and Excavations

What OTHER FLIPSCREEN USERS say

Industries

Industries

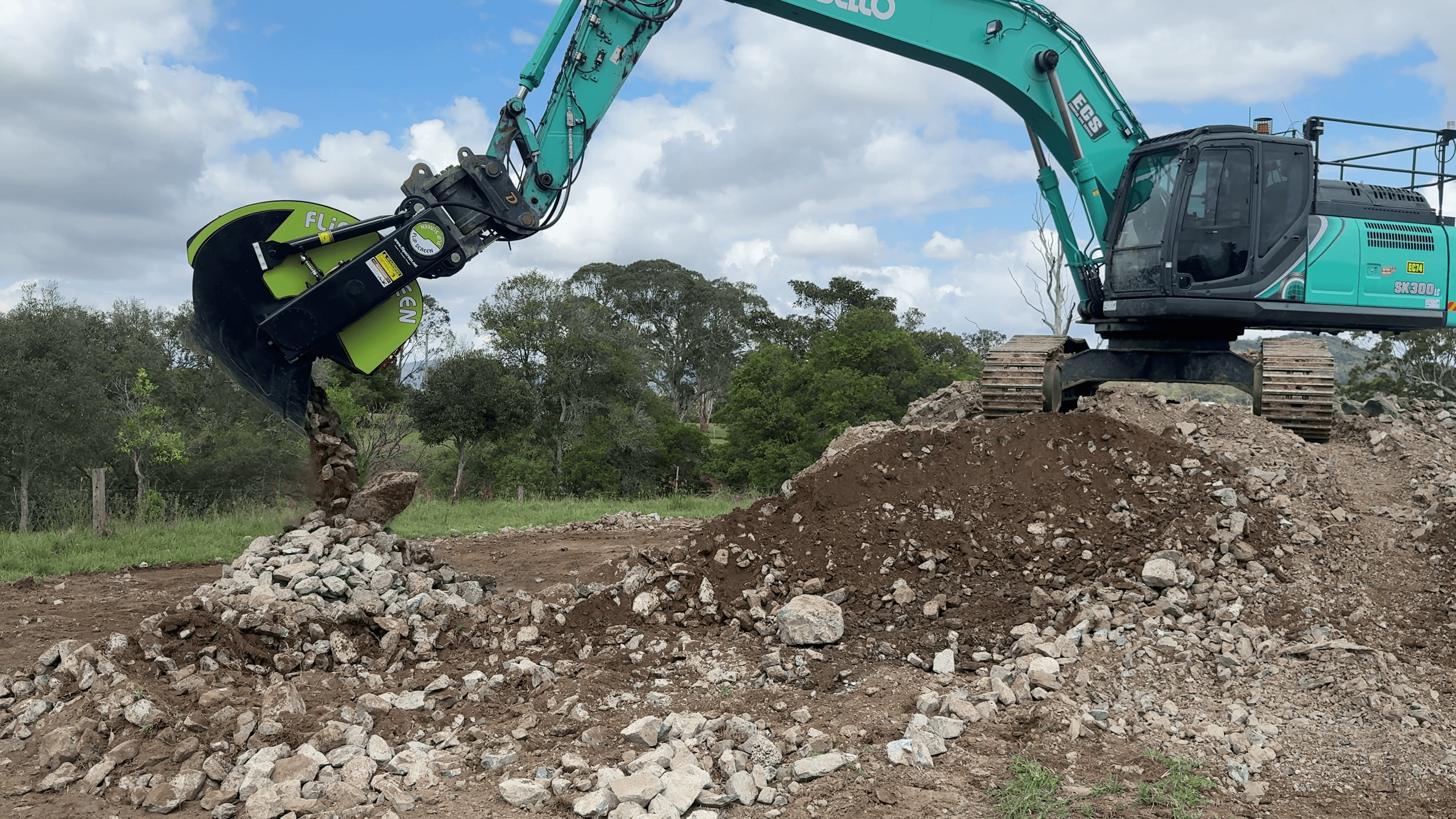

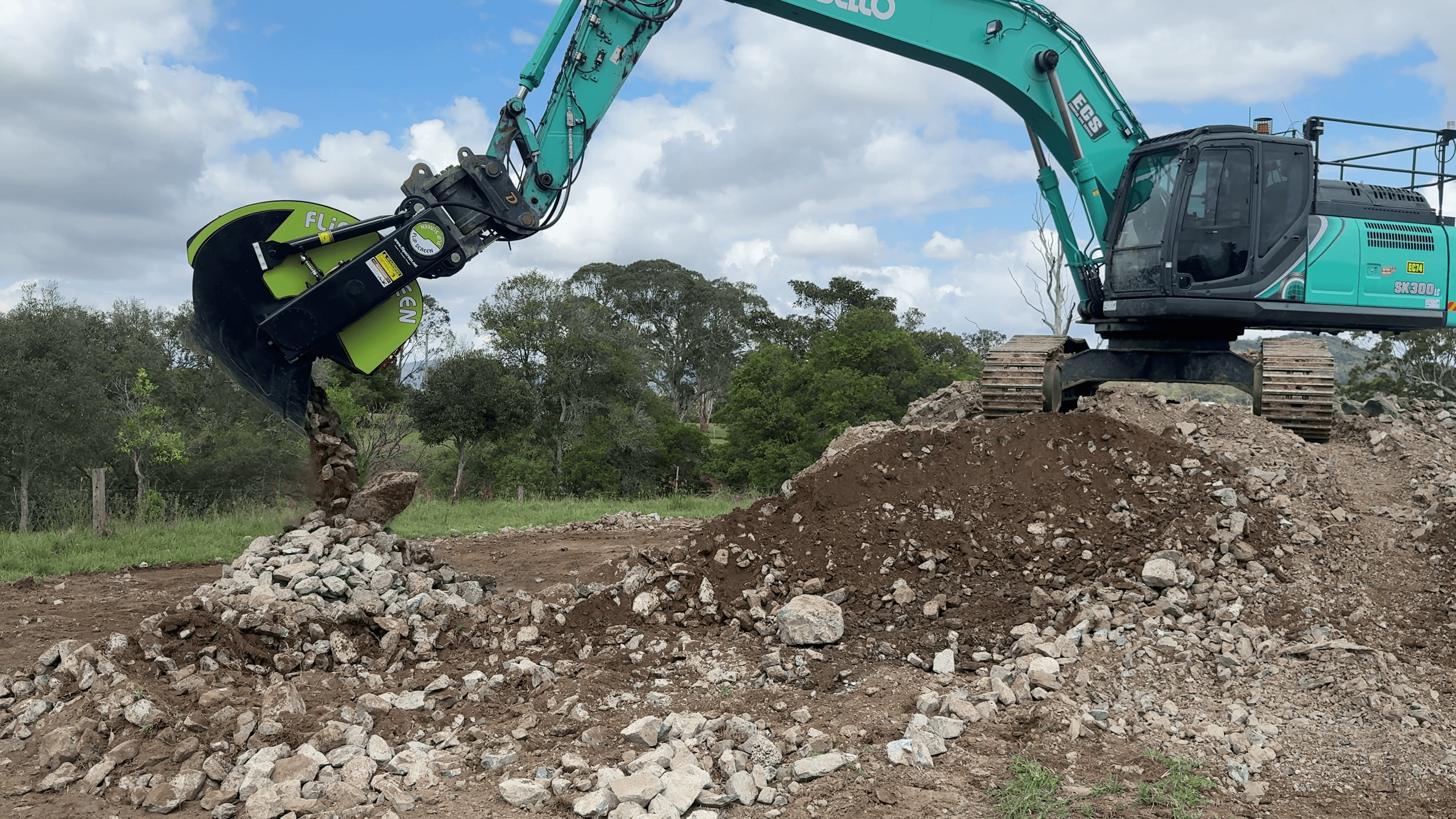

TALK TO A FLIPSCREEN EXPERT TODAY

Speak with your closest FlipScreen representive today to discuss the benefits of using a FlipScreen attachments and how best we can help your screening goals.

TALK TO A FLIPSCREEN EXPERT TODAY

Speak with your closest FlipScreen representive today to discuss the benefits of using a FlipScreen attachments and how best we can help your screening goals.

TALK TO A FLIPSCREEN EXPERT TODAY

Speak with your closest FlipScreen representive today to discuss the benefits of using a FlipScreen attachments and how best we can help your screening goals.